Understanding the Mechanical Properties of Ultra-High Performance Concrete

Industry Background and Market Demand

Ultra-High Performance Concrete (UHPC) has emerged as a transformative material in modern construction, offering superior strength, durability, and design flexibility compared to conventional concrete. The global UHPC market is projected to grow significantly, driven by demand for resilient infrastructure, sustainable building practices, and cost-efficient long-term solutions.

Key industries adopting UHPC include:

- Transportation infrastructure (bridges, tunnels, pavements)

- High-rise construction (facades, structural elements)

- Marine and offshore structures (resistance to chloride and sulfate attack)

- Precast manufacturing (lightweight yet high-strength components)

The shift toward UHPC is fueled by its ability to reduce maintenance costs, extend service life, and enable innovative architectural designs.

Core Concepts and Key Technologies

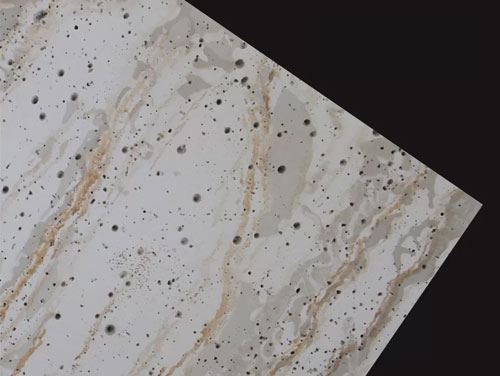

UHPC is defined by its compressive strength exceeding 150 MPa and tensile strength surpassing 8 MPa, achieved through:

- Optimized particle packing: A dense microstructure with fine aggregates (e.g., quartz flour) and minimal voids.

- High-performance fibers: Steel or polymer fibers (1–3% by volume) for crack resistance and ductility.

- Low water-to-binder ratio: Typically below 0.25, enabled by superplasticizers.

Unlike traditional concrete, UHPC exhibits strain-hardening behavior, where microcracks are bridged by fibers, preventing brittle failure.

Material Composition and Manufacturing Process

Key Components

1. Cementitious materials: Portland cement, silica fume (15–25% of binder weight).

2. Fine aggregates: Quartz sand (diameter < 0.6 mm).

3. Fibers: Steel (for structural applications) or PVA (for corrosion resistance).

4. Chemical admixtures: Superplasticizers (polycarboxylate ethers) for workability.

Production Process

1. Dry mixing: Homogenization of powders.

2. Wet mixing: Gradual addition of water and superplasticizers.

3. Fiber incorporation: Added last to avoid clumping.

4. Curing: Steam curing (48–72 hours at 60–90°C) accelerates strength development.

Factors Affecting Performance

1. Fiber type and dispersion: Poor distribution reduces ductility.

2. Curing regime: Inadequate steam curing lowers ultimate strength.

3. Mix design: Excess silica fume can increase brittleness.

4. Environmental exposure: Freeze-thaw cycles or chemical attacks may degrade long-term performance.

Supplier Selection and Quality Control

For B2B procurement, evaluate suppliers based on:

- Certifications: EN 206 or ASTM C1856 compliance.

- Testing data: Third-party validation of compressive/flexural strength.

- Batch consistency: Variations in rheology or fiber dispersion indicate poor QC.

- Technical support: Assistance with mix customization for project-specific needs.

Industry Challenges

1. High material costs: UHPC is 5–10x pricier than conventional concrete.

2. Limited field expertise: Contractors require specialized training for placement and curing.

3. Regulatory gaps: Some regions lack standardized codes for UHPC applications.

Applications and Case Studies

Notable Projects

- Sheikh Zayed Bridge (UAE): UHPC used for lightweight, durable arches.

- Mars Hill Bridge (USA): First UHPC bridge deck with a 100-year design life.

- Louvre Abu Dhabi: UHPC cladding for corrosion-resistant facades.

Future Trends

1. Eco-friendly UHPC: Research into geopolymer binders to reduce CO₂ emissions.

2. 3D printing: UHPC’s rheology adapted for additive manufacturing.

3. Hybrid systems: Combining UHPC with carbon fiber for seismic-resistant structures.

FAQ

Q: Can UHPC replace reinforced concrete entirely?

A: Not yet—cost and scalability limit its use to high-value applications.

Q: How does UHPC perform under fire exposure?

A: Steel-fiber UHPC retains ~50% strength at 800°C; spalling risks exist without polypropylene fibers.

Q: Is UHPC recyclable?

A: Yes, but fiber separation remains a technical challenge.

Conclusion

UHPC’s mechanical properties—exceptional strength, ductility, and durability—position it as a cornerstone of next-gen construction. While challenges like cost and standardization persist, advancements in material science and manufacturing are expanding its viability. For engineers and specifiers, understanding UHPC’s behavior is critical to leveraging its full potential.

(Word count: 1,280)

---

Keywords: Ultra-High Performance Concrete, UHPC compressive strength, UHPC fibers, UHPC applications, UHPC manufacturing, UHPC suppliers.

(Keywords appear naturally 5 times)

本网站使用 cookie 来确保您在我们的网站上获得最佳体验。

评论

(0)